Thiết kế cho sản xuất và lắp ráp - Design for Manufacturing and Assembly (DfMA)

Design for Manufacturing and Assembly (DfMA) is a key pillar of Singapore’s Construction Industry Transformation Map (ITM). It is a game-changing method of construction which involves construction being designed for manufacturing off-site in a controlled environment, before being assembled on-site.

Key benefits of DfMA include:

- Shorter construction period– Most of the construction is done off-site, reducing the construction time and the amount of manpower required on-site

- Improved workmanship– Due to stringent quality control in prefabrication factories

- Reduction in dis-amenities– As lesser construction work is carried out on-site, it causes less disruption to the community

Types of DfMA technologies

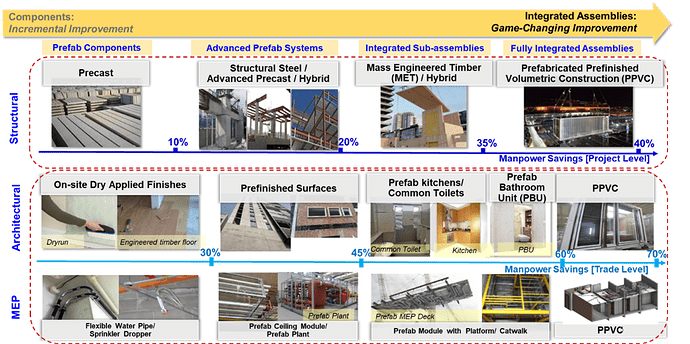

DfMA comprises a continuum of various technologies and methodologies that promote offsite fabrication from prefabricated components to fully integrated assemblies across the structural, architectural and MEP disciplines.

| Advanced Precast Concrete System (APCS) | A construction method that adopts precast concrete components and applies features under the ‘3S’ principles of Standardisation, Simplicity and Single. |

|---|---|

| Mass Engineered Timber (MET) | A building material comprising engineered wood products with improved structural integrity. |

| Prefabricated Prefinished Volumetric Construction (PPVC) | A construction method whereby free-standing 3-dimensional modules are completed with internal finishes, fixtures and fittings in an off-site fabrication facility, before it is delivered and installed on-site. |

| Prefabricated Bathroom Units (PBU) | A bathroom module which is preassembled off-site complete with finishes, fixtures and sanitary wares before it is delivered and installed on-site. |

| Prefabricated Mechanical Electrical and Plumbing (MEP) System | MEP components and equipment that are integrated into a sub-assembly off-site and then installed on site. |

| Structural Steel | A category of steel used for making construction materials, such as beams and joints. |

Click on the individual technologies to read more.

How Singapore is encouraging adoption of DfMA

| Integrated Construction and Prefabrication Hubs (ICPH) | To support the increasing demand for DfMA components, Singapore is developing Integrated Construction and Prefabrication Hubs (ICPHs) with a 30-year lease term. |

|---|---|

| Generating Demand for DfMA projects | Driving adoption of DfMA is driving adoption of DfMA through Productivity Gateway Framework (PGF) and Government Land Sales (GLS) requirements. |

| Pipeline of DfMA projects | Pipeline of projects prescribing DfMA technologies – for construction tenders expected to be called within the next two years. |